Week 5 through 12. Yep we worked through the holidays without missing a beat. This takes us up to January 26th.

Looking back, here we were December 9 ahead of the holidays and a new year.

The Panzer II Luchs has a relatively wide stance for the width of the hull. The final drives stick out a bit.

These hunks of steel push our m113 final drives to the correct track to track width spacing.

Here's Dave metal glueing them in place.

Eddie hooking up the new torsion bar hubs with new bushings and seals.

New hubs, new bushings, new seals

New torsion bars.

First fitting of the motor in Omega.

Tad fashioning a temp bracket to hold the engine assembly where it should be.

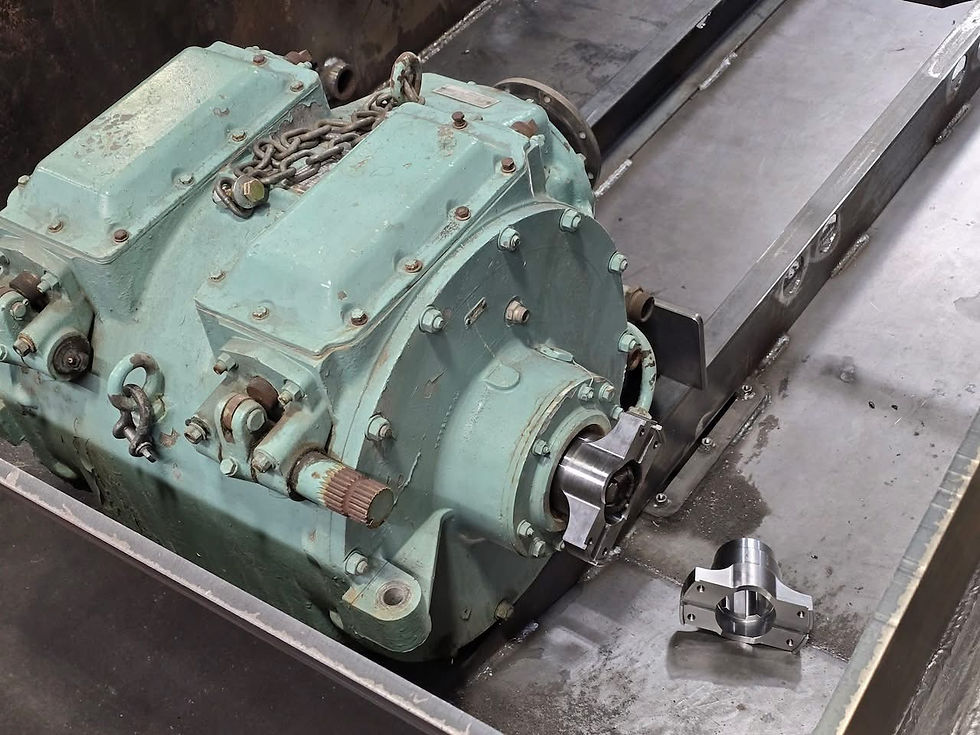

Mike is sidetracked pushing our Panzer IV main gun elevation gearbox restoration forward.

Panzerfabrik design swing arm hub assembly. It combines M113 parts with custom made parts to make a better Luchs. Swing arms will press and pin onto this assembly. You can see the end of a torsion bar stuck into the hub. Those plate extensions will be welded up later once tacked exactly where they need to be.

One by one the hubs, plates and anchors are massaged to provide for a smooth torsion bar fit. If they don't line up, the torsion bars won't peacefully slide into place... Everything has to be in a straight line for it to work.

Now the welding of the extensions.... NO!!! STOP. If I could only go back in time we could prevent the upcoming disaster.

Beautifully welded... uhhhh yes and no. Even with great effort to control the temperature of the welding we got enough heat distortion in the sidewalls that the torsion bars won't willingly slide in and out. AHHHH !!!

So Michael had to spend the better part of 3 weeks, heating, pressing, jacking and cussing to get the sidewalls straight enough to allow harmony with the torsion bars. Added the floor bracing to lock it all in place.

Eddie making the rear tow hitch for Omega

Swapping over to a U.S. style U-joint required having these babies made. Now we can run commonly found U-joints instead of the crazy British system.

Dave making 2 rear exhaust armor covers.

Some spice for the front. Detailed copy of feature present on both remaining original Luchs.

Adding the spare track hanger bar.

Fire wall. Cool! Now we can start laying out the interior.

Now it's more than just a shell. Chalking out the kit that affixes to the wall on the right inner side. Lance has been an amazing finder and coordinator of new information. Figuring out how the original Luchs interior is laid out has been a challenge.

Comments